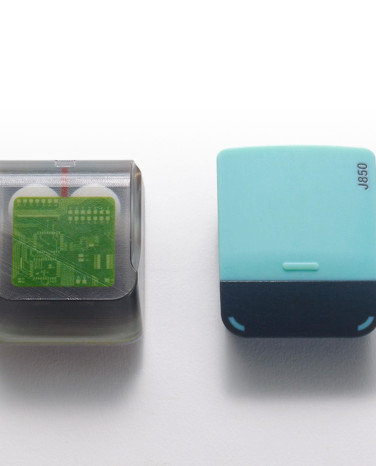

PJ (Poly Jet) / Multi Jet Modelling (MJM)

W technologiach żywicznych opartych na technice PJ (PolyJet) i MJM (Multi Jet modeling) materiałem przetwarzanym jest tworzywo w postaci światłoczułej żywicy. Proces polimeryzacji odbywa się poprzez działanie lampy UV, która realizuje proces polimeryzacji selektywnie nałożonych przekrojów wytwarzanego modelu.

Technologie żywiczne wykorzystywane w bardzo szerokim zakresie aplikacji, np.: motoryzacja, biotechnologia, medycyna oraz jubilerstwo. Duża precyzja wykonania części oraz szeroka gama materiałów to dodatkowe atuty tych technologii. Dla zaawansowanych geometrii wymagane jest zastosowanie struktur wspierających, które w większości przypadków można usunąć stosunkowo łatwo poprzez rozpuszczenie lub wypłukanie strumieniem cieczy. Jeśli struktury wspierające okazują się problematyczne w twoim projekcie, sprawdź technologię SLS.

Benefity technologii SLA / DLP

Benefit #1

Wysoka rozdzielczość wytwarzanych części dzięki ultra cienkiej grubości warstwy (od 16 µm)

Benefit #2

Możliwość wytwarzania części wielomateriałowych w ramach jednej części

Benefit #3

Duży wybór materiałów ( od materiałów gumo podobnych do twardych)

Benefit #4

Stosunkowo łatwa obróbka wykańczająca

Materiały

-

Żywica standard

-

Żywice imitujące właściwościami tworzywa inżynierskie: ABS-like, PP-like

-

Żywica elastyczna

-

Żywica wysokotemperaturowa

-

Żywica super clear

-

Żywica odlewnicza

-

Żywica dentystyczne/medyczne

Najbardziej popularna żywica, która charakteryzuje się sztywnością.

Żywice te swoimi właściwościami mechanicznymi zbliżone są do ABS oraz PP.

Żywica zbliżona właściwościami do gumy.

Żywica przeznaczona do aplikacji pracujących w podwyższonych temperaturach (do 80 st. C).

Materiał przeznaczony do aplikacji gdzie wymagana jest wysoka transparentność. Możliwa dalsza obróbka, która pozwala uzyskać niemal 100% transparentności.

Materiał zaprojektowany tak, aby pozostawiać po sobie minimalne produkty spalania podczas usuwania modelu z formy. Stosowany w odlewnictwie. Jeśli szukasz materiału dla odlewnictwa dla większych serii oraz dla większych gabarytów, sprawdź SLS / Primecast

Żywica stosowana w medycynie. Posiada certyfikat biokompatybilności.

Jeśli szukasz innego materiału z certyfikatami medycznymi, sprawdź SLS/PA12

Koszt druku 3d i czas realizacji dostawy

Co wpływa na koszty oraz czas realizacji w technologiach żywicznych

-

objętość części

objętość części -

zastosowany materiał

zastosowany materiał -

zastosowane parametry (np. grubość warstwy)

zastosowane parametry (np. grubość warstwy) -

konieczność stosowania suportów - sprawdź inne technologie bez supportu

konieczność stosowania suportów - sprawdź inne technologie bez supportu -

wielkość serii produkcyjnej

wielkość serii produkcyjnej -

zastosowany postprocessing - więcej informacji w postprocessing

zastosowany postprocessing - więcej informacji w postprocessing -

wybór opcji realizacji express

wybór opcji realizacji express

Chcesz zoptymalizować koszty?

Chcesz zoptymalizować koszty?

Zasady projektowania dla technologii żywicznych

W technologii PJ i MJM zalecamy stosować się do następujących zasad:

minimalna średnica otworu 2 mm

minimalna grubość ścianki od 0,6 mm w zależności od geometrii

należy zapewnić dostęp do obszarów z suportem w celu jego usunięcia

piny pozycjonujące powinny mieć grubość/średnicę co najmniej 2 mm

Potrzebujesz pomocy w projekcie?

Potrzebujesz pomocy w projekcie?