Discover the endless application possibilities of our Additive Manufacturing technologies

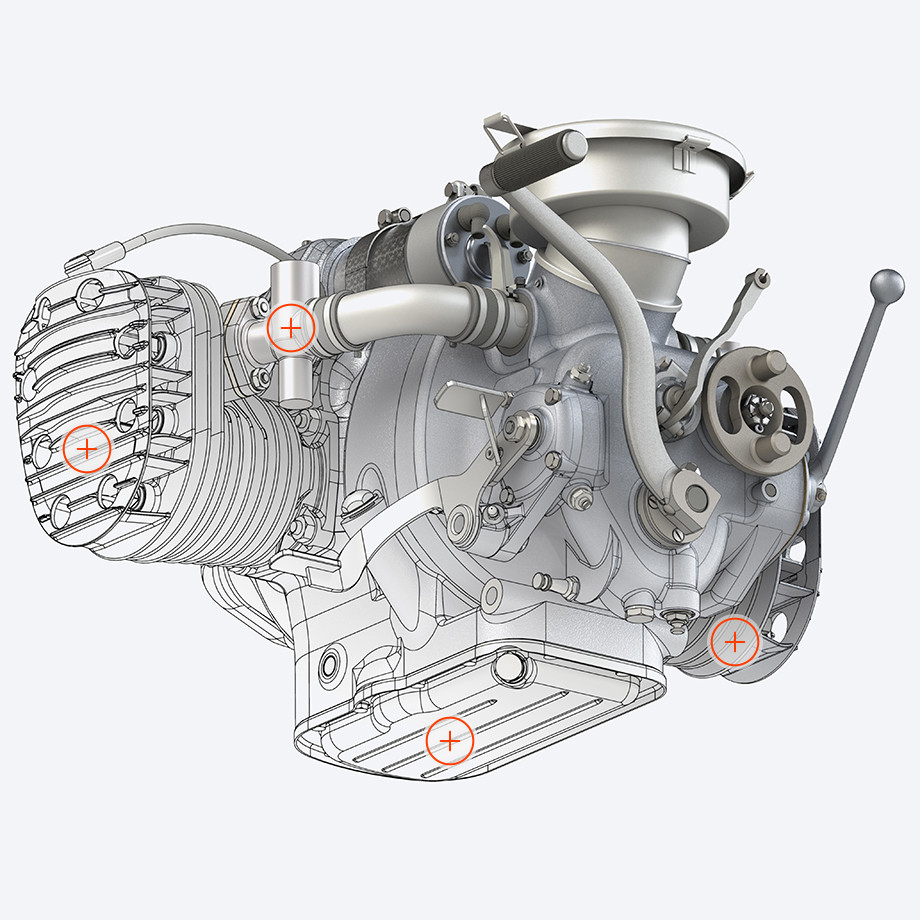

Click on the hotspots

to see how they are made

Send a personalized request – our experts

will contact you and prepare a free quote.

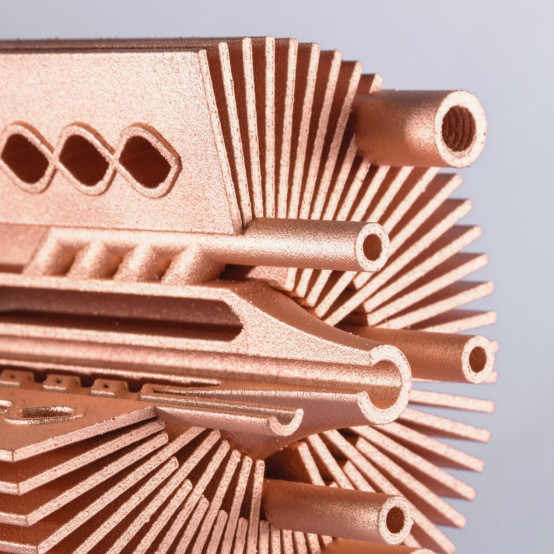

DMLS/SLM Technology

Whenever you need a considerable amount of time and money to start conventional production of parts or tools from metal alloys, you can use DMLS / SLM and Rapid Casting technologies. Thanks to this, you can get quality parts from numerous metal alloys without large financial investments. You can use tool steels such as MaragingSteel MS, ToolSteel 1.270, ToolSteel H13 or high-alloy steels such as 316L, PH1, 17-4PH, aluminium alloys, titanium alloys, nickel alloys and other less frequently used alloys that are also available. Find out more about the materials here.

FDM/FFF Technology

Thanks to the FDM / FFF technology, we will create durable and ergonomic production tooling for you (jigs and fixtures). High-strength polymer materials will allow you to use the FDM / FFF technology in an aggressive work environment. ABS is the most commonly used material, but highly specialized materials, such as PEEK or ULTEM, are also available. If you need more information about the materials, check here.

CAD Design

Our team of designers has the unique ability to maximize the benefits of 3D Printing in manufacturing. We will help you at every stage of your product development and support you with the optimization of an existing solution.

SLS Technology

Using SLS technology, you can manufacture high-quality parts from durable polymer engineering materials. You have different products at your disposal, from certified and non-flammable materials (PA2241FR), through high-impact and resistant materials (PA11), to the materials of general use (PA12). You can find more details about the materials here. SLS technology can be successfully used during product development, but also for serial production as well as in the final product for your application.

First time with Additive Manufacturing?

What do we offer?

Product Innovation Services

Recognize the potencial in your product

At this stage, a project analysis is carried out in which we pay special attention to the validity of the solution, the structural solutions, the possibility of optimizing the structural part, the materials involved, the working environment or specific product requirements. The result of this stage is a detailed report on the basis of which the next steps can be implemented.

Recognize the potencial in your product

At this stage, a project analysis is carried out in which we pay special attention to the validity of the solution, the structural solutions, the possibility of optimizing the structural part, the materials involved, the working environment or specific product requirements. The result of this stage is a detailed report on the basis of which the next steps can be implemented.

Design for Additive Manufacturing

After a thorough analysis and agreed structural and technological changes for additive technologies, prototypes are produced to assess the validity of the original idea.

Design for Additive Manufacturing

After a thorough analysis and agreed structural and technological changes for additive technologies, prototypes are produced to assess the validity of the original idea.

Prototyping and validation

This stage allows you to verify the assumptions and evaluates in a laboratory and physical way, the product that has undergone the process. The number of iterations depends on reaching a satisfactory level of acceptance which, apart from its functional value, will meet other added values.

Prototyping and validation

This stage allows you to verify the assumptions and evaluates in a laboratory and physical way, the product that has undergone the process. The number of iterations depends on reaching a satisfactory level of acceptance which, apart from its functional value, will meet other added values.

New Business model

The validity of the implementation of the product for use becomes a companion to the cost-effectiveness of the implementation. This is the stage at which decisions are made about the production and investment before the company or the implementation of the strategy of a contract manufacturing / OEM partnership.

New Business model

The validity of the implementation of the product for use becomes a companion to the cost-effectiveness of the implementation. This is the stage at which decisions are made about the production and investment before the company or the implementation of the strategy of a contract manufacturing / OEM partnership.

Scale the business

Preparation of the business line, standards and quality procedures to be implemented to replace existing products with products from additive technologies

Scale the business

Preparation of the business line, standards and quality procedures to be implemented to replace existing products with products from additive technologies