3d printing MJF

Multi Jet Fusion (MJF) belongs to the Additive Manufacturing Powder Bed group of technologies. It has one of the largest production potentials in the 3D printing industry.

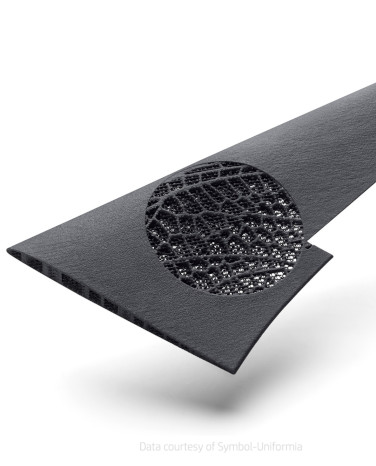

Similar to SLS technology, MJF models are built in layers, but the way the heat energy is delivered is solved by selectively increasing light absorption and by spraying black dye onto a powder layer, and then welding the selected section with a lamp as an energy emitter. The shaded sections absorb more energy and the layer is solidified with the previous layer. This technology gives the possibility to make both prototypes and utility parts. Models are light gray, they can be colored black or another dark color.

What are the benefits of MJF?

Benefit #1

High productivity

Benefit #2

Cost-effective production of high-quality parts without the use of expensive conventional forming tools

Benefit #3

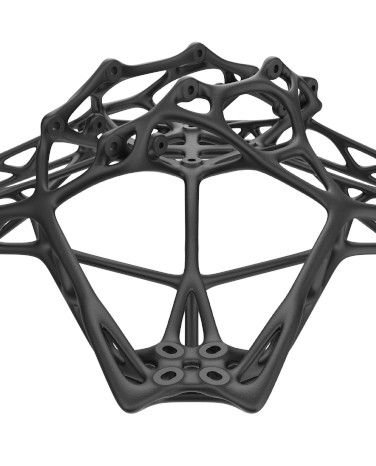

Parts after optimization may have better parameters and unique properties

Benefit #4

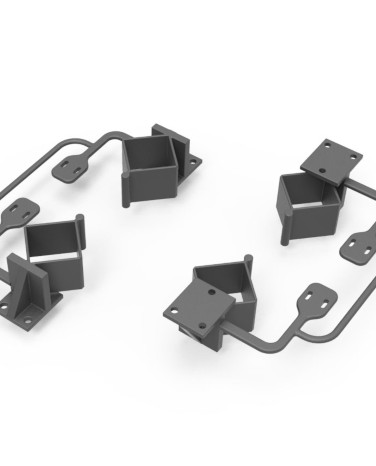

No need for supporting structures

Materials

Other names: Polyamide 12, Nylon 12. The material is used most widely in MJF technology. The high durability of the made parts gives the possibility to apply this material across many industries. It is suitable for both prototyping and production of parts for the final assembly. The produced parts are light grey, they can be coloured black and other dark colours.

-

High durability

High durability -

USP Class I-VI certification and Food and Drug Administration (FDA) regulation for equipment in contact with undamaged skin

USP Class I-VI certification and Food and Drug Administration (FDA) regulation for equipment in contact with undamaged skin -

High chemical resistance

High chemical resistance -

Machineable: smoothing, painting, staining

Machineable: smoothing, painting, staining

Other names: TPU 90A-01. It is a thermoplastic polyurethane, characterized by high flexibility. It is ideal where the properties should be similar to the properties of rubber.

-

High flexibility

High flexibility -

Abrasion resistance

Abrasion resistance

Costs and Lead Time

What influences costs and lead time in MJF

-

Part capacity (machine work chamber space)

Part capacity (machine work chamber space) -

Used material

Used material -

Production series size

Production series size -

Cleaning unsintered powder from complex geometries

Cleaning unsintered powder from complex geometries -

Applied postprocessing - more information in postprocessing

Applied postprocessing - more information in postprocessing -

Choosing express execution options

Choosing express execution options

Want to optimize costs?

Want to optimize costs?

MJF design guidelines

For MJF technology, we recommend that you follow these rules:

Minimum hole diameter 2 mm

Minimum wall thickness 1 mm

The minimum clearance for moving parts is 0.5 mm

Positioning pins should be at least 3 mm thick/medium

The dimensional tolerance in SLS is +/- 0.3 % of the dimension measured at the lower limit +/- 0.3 mm

In MJF, it is not recommended to use massive cross-sections (above 5 mm), because it runs the risk of deformation

Use technical holes to evacuate the powder in confined spaces (if unsintered powder needs to be removed)

Not sure about your design?

Not sure about your design?